SPECgrade Heavy Duty Industrial Electrical Fittings

Times Have Changed and So Should Your Fittings, It is Time to Consider

The Next Generation of Electrical Fittings for Harsh & Hazardous Environments

SPECgrade Electrical Fittings

Our specification grade electrical fittings are designed and manufactured to keep the food and beverage industry efficient and code compliant while ensuring workplace safety and reducing downtime.

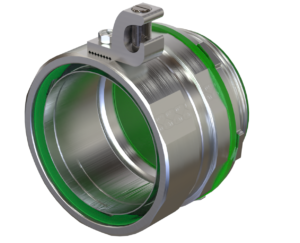

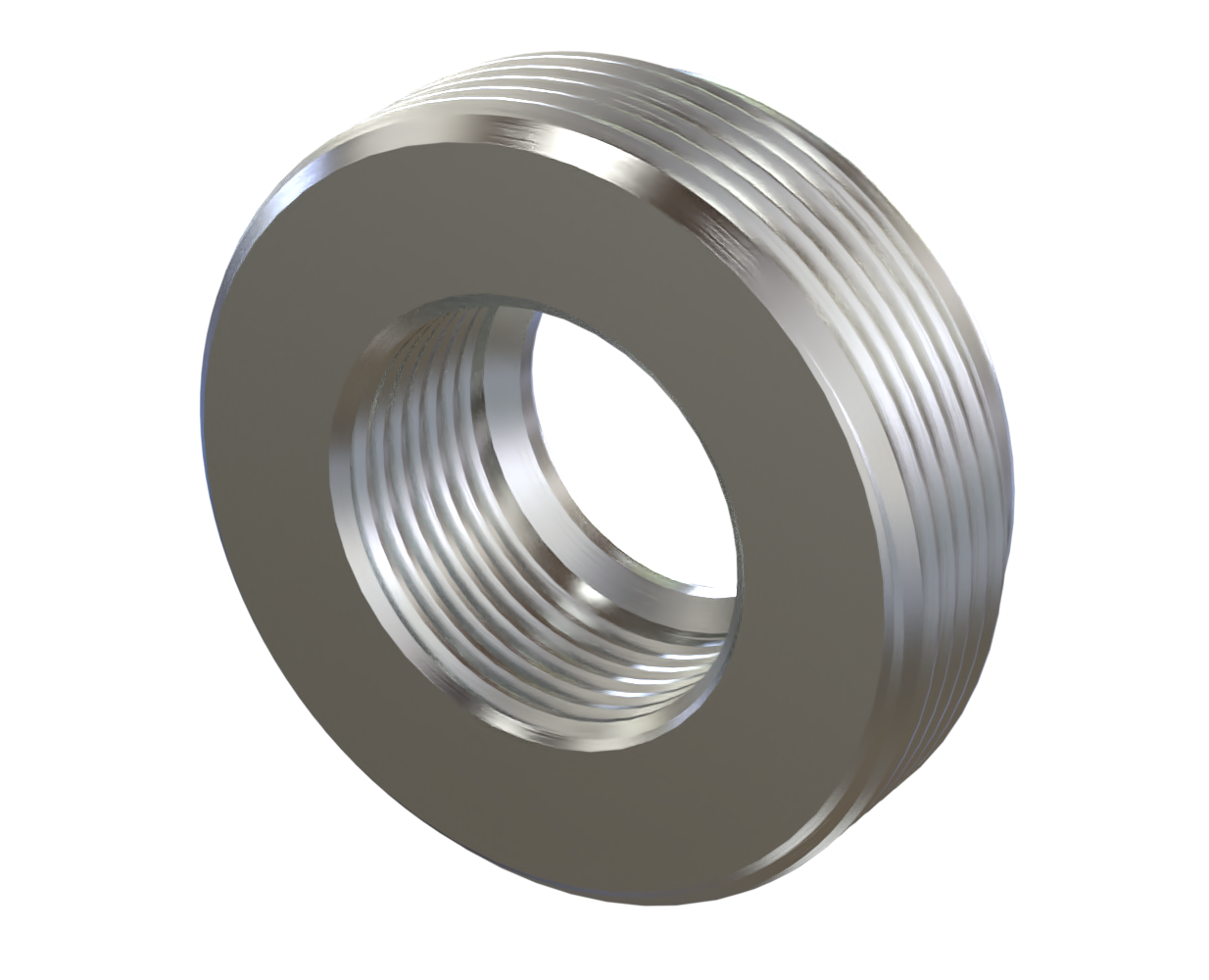

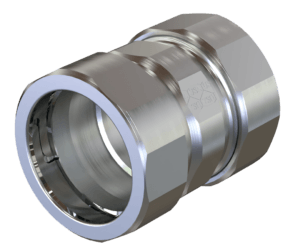

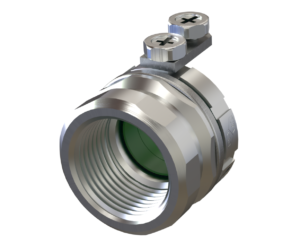

Solid bar stock construction, precision machined provide the ultimate in environmental protection in your facility or on equipment. Every fitting locks tight and right and will never vibrate loose or expose threads to contaminants.

We Meet the Most Demanding Requirements, OUR OWN !

Food processing facilities get cleaned and sanitized regularly, exposing vital machinery to liquids and contaminants that threaten both safety and reliability. Since contamination and corrosion are unacceptable, power handling equipment and their components must withstand the elements and fight off threats.You can be assured that all our fittings are built to withstand washdown and corrosive agents in demanding food processing environments.

You be assured that our products are built to withstand washdown and corrosive agents in demanding food processing environments. All AMFICO fittings are listed, meet and/or exceed performance requirements from Underwriters Laboratory (UL) and the Canadian Standards Association (CSA). Please see individual products for specific listing information.

When you utilize American Fittings , you buy from an American, family-owned manufacturing company. All our products are manufactured in our manufacturing headquarters in Fair Lawn, NJ. No other electrical fitting manufacturer sells more US Made steel electrical fittings that us. Its that simple.

Every fitting is built with our Seal of INTEGRITY:

- WE KNOW the DNA of every piece of raw material we utliize.

- WE KNOW the machine, operator, date and time the component and fitting was manufactured by us.

- WE KNOW the inspector and protocol used to inspect our fittings.

- WE KNOW the date, time and packaging person who packaged our fittings.

- WE KNOW you cannot buy a better fitting- THAT WE GUARANTE

Perfect for the Most Demanding Conditions

AMFICO Fittings are ideal in facilities / plant areas that need to be continually washed and disinfected to prevent contamination. These areas include poultry and meat packing facilities, food processors, and bottling facilities. Food preparation areas may have requirements for temperature ratings such as low temperatures for freezer rooms. As a result, equipment and devices in these areas need to meet specific requirements to allow for the wash down conditions, extreme temperatures, etc. AMFICO electrical fittings feature:

- UL Listed, Approved and Tested

- Manufactured in the US in our facility in Fair Lawn, NJ

- Hygienic design in accordance with EN1672-2 & EN ISO 14159

- Smooth finish eliminates build up of bacteria & micro-organisms

- Liquid Tight, Dust Tight Ratings by UL, Meeting NEMA 4X

Stainless Steel Fittings

- Perfect for high corrosion environments with acids, chemicals and chlorine-bearing agents

- Excellent durability, tensile strength, temperature, fatigue and impact resistance

- Low maintenance, smooth and almost non-porous surface, hygienic and easy to clean

- Operating temperature: -60°F to +1000° F

Aluminum Fittings

- High corrosion resistance to alkalis, weak acids and moisture, excellent rust-resistance in environments with high humidity

- Lightweight with high wear resistance

- Affordable alternative to stainless steel

- Operating temperature: -40°F to +500° F

Alloy Steel – Zinc Plated with Chromate Finish

- Good corrosion resistance to hydrocarbons, fuels, solvents and neutral chemicals

- High durability, tensile strength and impact-resistance

- Extremely high fatigue endurance

- Very high moisture resistance

- Operating temperature: -40°F to +290° F