SPEC grade Industrial Fittings for Airport Construction, Aerospace, and FAA Projects

SPECgrade Electrical Fittings

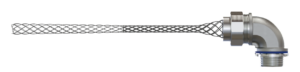

Our specification grade electrical fittings are designed and manufactured to keep the construction industry and their infrastructure projects efficient and code compliant while ensuring workplace safety and reducing downtime. The correct fitting makes the installation process easier while ensuring a safe, durable electrical system.

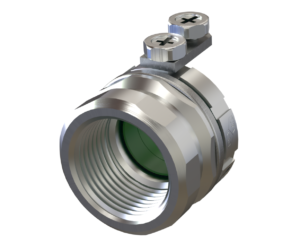

On these heavy-duty construction projects, electrical fittings are not the place to cut corners. We offer the most extensive selection of infra-structured fittings Integrity in high-quality materials, integrated fully controlled manufacturing processes provide your assurances. Solid bar stock construction, precision machined provide the ultimate in environmental protection in your facility or on equipment. Every fitting locks tight and right and will never vibrate loose or expose threads to contaminants.

We Meet the Most Demanding Requirements, OUR OWN !

Food processing facilities get cleaned and sanitized regularly, exposing vital machinery to liquids and contaminants that threaten both safety and reliability. Since contamination and corrosion are unacceptable, power handling equipment and their components must withstand the elements and fight off threats.You can be assured that all our fittings are built to withstand washdown and corrosive agents in demanding food processing environments.

You be assured that our products are built to withstand washdown and corrosive agents in demanding food processing environments. All AMFICO fittings are listed, meet and/or exceed performance requirements from Underwriters Laboratory (UL) and the Canadian Standards Association (CSA). Please see individual products for specific listing information.

When you utilize American Fittings, you buy from an American, family-owned manufacturing company. All our products are manufactured in our manufacturing headquarters in Fair Lawn, NJ. No other electrical fitting manufacturer sells more US Made steel electrical fittings that us. Its that simple.

Every fitting is built with our Seal of INTEGRITY:

- WE KNOW the DNA of every piece of raw material we utilize.

- WE KNOW the machine, operator, date, and time the component and fitting were manufactured by us.

- WE KNOW the inspector and protocol used to inspect our fittings.

- WE KNOW the date, time, and packaging person who packaged our fittings.

- WE KNOW you cannot buy a better fitting- THAT WE GUARANTEE

Ideal for Your Demanding Conditions

AMFICO Fittings are ideal on construction sites are that require zero tolerance for an inferior, offshore, camouflaged fitting. Outdated malleable iron or truly subpar diecast do not belong on any specification where durability and long life are essential for success. Alloy steel fully outperforms and installs faster and more reliable than antiquated malleable. Learn More →

- UL Listed, Approved and Tested

- Completely Manufactured in our Facility in Fair Lawn, NJ

- EZ Torque Compression Nuts, Seal Tight & Right

- Products made from Solid Bar Stock & Precision Machined

- Galvanized Plating options, Power Coated, and Zinc Chromate Plating

- Guaranteed Rain Tight Option with Gold Toned Nut for EZ Inspection

- Smooth ID Surfaces Eliminates Wire/Cable Grab on Long Pulls

- Vibration Resistant

- Meet Mil-Std 810 for Sinusoidal Vibration Rating

- Liquid Tight, Dust Tight Ratings by UL, Meeting NEMA 4X

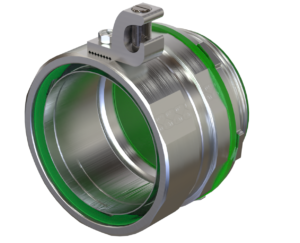

Stainless Steel Fittings

- Perfect for high corrosion environments with acids, chemicals and chlorine-bearing agents

- Excellent durability, tensile strength, temperature, fatigue and impact resistance

- Low maintenance, smooth and almost non-porous surface, hygienic and easy to clean

- Operating temperature: -60°F to +1000° F

Aluminum Fittings

- High corrosion resistance to alkalis, weak acids, and moisture, excellent rust-resistance in environments with high humidity

- Lightweight with high wear resistance

- Affordable alternative to stainless steel

- Operating temperature: -40°F to +500° F

Alloy Steel – Zinc Plated with Chromate Finish

- Good corrosion resistance to hydrocarbons, fuels, solvents and neutral chemicals

- High durability, tensile strength, and impact-resistance

- Extremely high fatigue endurance

- Very high moisture resistance

- Operating temperature: -40°F to +290° F