Electrical Fittings

Steel vs Malleable Iron and Die Cast

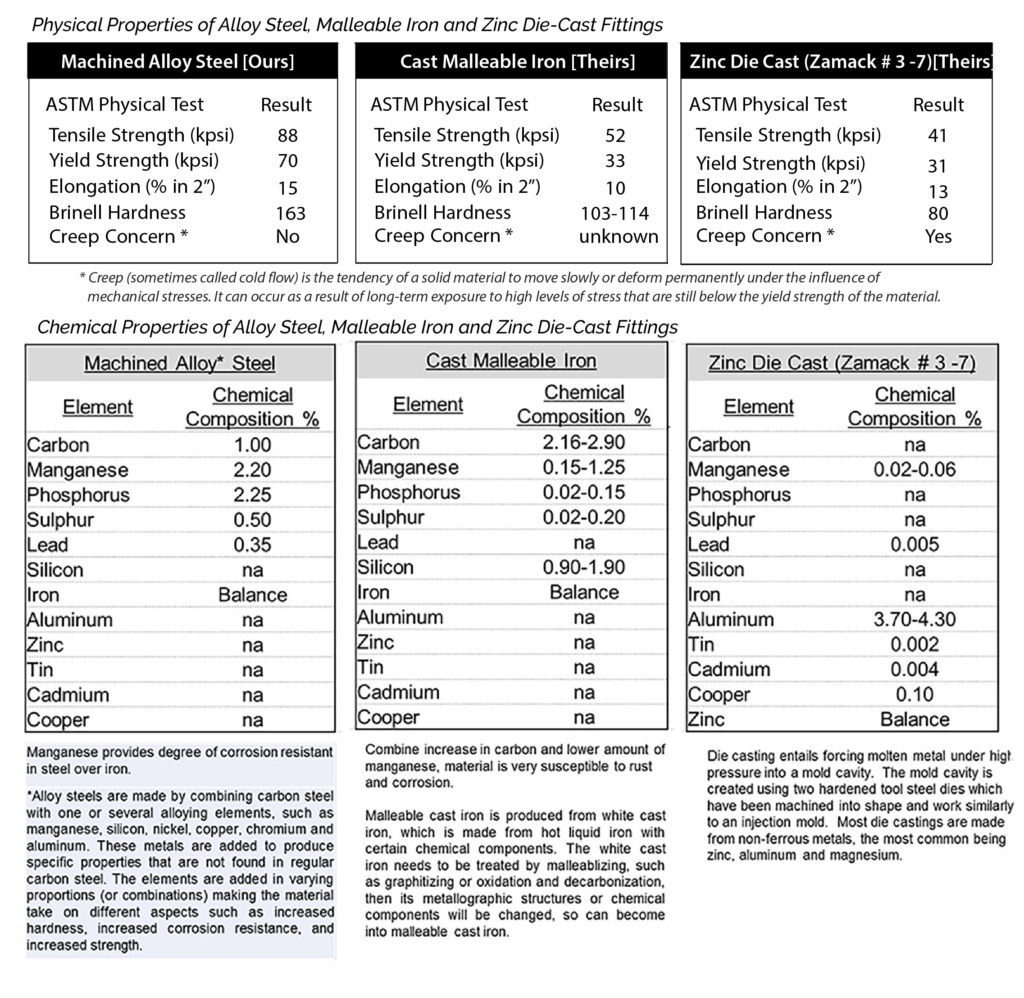

Consider the Major Differences in Materials

Weak threads are the #1 cause of environmental & mechanical fitting failure. Malleable Iron fittings weigh two to 3 times that of steel fittings & Dimensionally are one and one-half times larger in size. Due to natural porosity diecast fittings crack & distort under load. Corrosion resistance and performance are equally telling.

When you combine alloy steel, zinc plated with a chromate finish there is no comparison on which fitting will hold up longer to extreme environmental conditions. In extreme cold die-cast will deform and deflect, malleable iron with chip and pit, while alloy steel maintains its natural characteristics.