American Fittings, SPECgrade Industrial Electrical Fittings

Out With the Old & Connect With the New.

Choose the Next Generation of Electrical Fittings for

All Your Construction Projects, Equipment and Upgrades

AMFICO Steel Fittings Twice the Strength of Die-Cast and 1/3 the Weight of Malleable.

SPECgrade Electrical Fittings

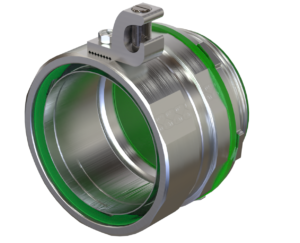

Our specification grade electrical fittings are designed and manufactured to keep the food and beverage industry efficient and code compliant while ensuring workplace safety and reducing downtime.

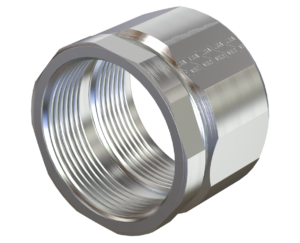

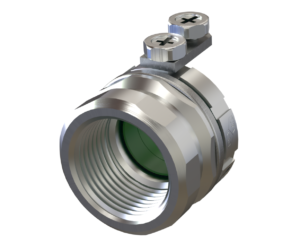

Solid bar stock construction, precision machined provide the ultimate in environmental protection in your facility or on equipment. Every fitting locks tight and right and will never vibrate loose or expose threads to contaminants.

Quick Product Links

Meeting the Most Demanding Conditions, Our Own!

Food processing facilities get cleaned and sanitized regularly, exposing vital machinery to liquids and contaminants that threaten both safety and reliability. Since contamination and corrosion are unacceptable, power handling equipment and their components must withstand the elements and fight off threats. You can be assured that all our fittings are built to withstand washdown and corrosive agents in demanding food processing environments.

You are assured that our products are built to withstand washdown and corrosive agents in demanding food processing environments. All AMFICO fittings are listed, meet, and/or exceed performance requirements from Underwriters Laboratory (UL) and the Canadian Standards Association (CSA). Please see individual products for specific listing information.

Buy With Confidence

When you utilize American Fittings, you buy from an American, 3rd generation family-owned manufacturing company. All our electrical fittings are engineered and manufactured in our headquarters in Fair Lawn, NJ. No other electrical fitting manufacturer sells more US Made steel electrical fittings than us. It is that simple. Since 1946 our brand is our name, American Fittings. . . it’s our commitment and your guarantee.

Every Fitting Carries Our Seal of INTEGRITY

- WE KNOW the DNA of every piece of raw material we utilize.

- WE KNOW the production machine, operator, date & time every component & fitting were manufactured by us.

- WE KNOW the QC inspector and protocols used to inspect our fittings.

- WE KNOW the date, time &t the packaging person who boxed your fittings.

- WE KNOW you cannot buy a better fitting- THAT WE GUARANTEE.

Since 1946, Brand Strong We Stand American.

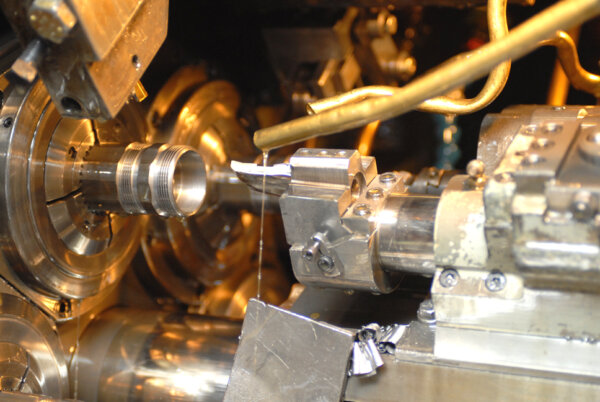

While other major fitting companies have closed US manufacturing and turned into “Big Box Stores” for China & India we have expanded our manufacturing facilities in NJ. Since 2011 production and equipment have expanded by 500%. From the latest in CNC manufacturing and robotic equipment to injection molding of our components, this investment provides our ability to grow and expand product lines. The NEXT GENERATION of fittings is being expanded. Since 1946 Family owned and operated for 3 generations we have grown into a leader in the market for industrial electrical fittings.

Read more about our company and management →

Ideal for Your Demanding Conditions

AMFICO fittings are the #1 choice of contractors looking to save money on their installation costs. End users and OEM equipment builders can improve and ensure the useful application and hookup for wiring to enclosures or motors. We keep things your project moving by focusing on exceptional on-hand inventory, fast turnaround, and the best customer service in the industry. You can assured that we build for quality and inspect for integrity.

- UL Listed, Approved and Tested

- Completely Manufactured in our Facility in Fair Lawn, NJ

- EZ Torque Compression Nuts, Seal Tight & Right

- Galvanized Coated Options, Power Coated, and Zinc Chromate Plating

- Rain Tight Option with Gold Toned Nut for EZ Inspection

- Smooth ID Surfaces Eliminates Wire/Cable Grab on Long Pulls

- Vibration Resistant

- Meet Mil-Std 810 for Sinusoidal Vibration Rating

- All Fittings Manufactured from Solid Bar Stock and Precision Machined to Guaranteed Tight Tolerances

Our Fittings are a Cut Above All the Rest

Alloy Steel

- Good corrosion resistance to hydrocarbons, fuels, solvents and neutral chemicals

- High durability, tensile strength, and impact-resistance

- Extremely high fatigue endurance

- TWICE the tensile strength of die-cast and malleable iron

- 1/3 the weight of malleable iron – less stress on support more efficient installation

- Operating temperature: -40°F to +290° F

Stainless Steel Fittings (Type 316)

- Perfect for high corrosion environments with acids, chemicals, and chlorine-bearing agents

- Excellent durability, tensile strength, temperature, fatigue and impact resistance

- Low maintenance, smooth and almost non-porous surface, hygienic and easy to clean

- Operating temperature: -60°F to +1000° F

Aluminum Fittings (6061T6)

- High corrosion resistance to alkalis, weak acids, and moisture, excellent rust-resistance in environments with high humidity

- Lightweight with high wear resistance

- Affordable alternative to stainless steel

- Operating temperature: -40°F to +500° F

Save Time on Installations & Improve Applications With Our Next Generation of Fittings

Our Fittings Speak for Themselves

Click on an image to view