Frequently Asked Questions

Click on a Topic to Learn More

Raceway systems such as EMT and rigid conduit are permitted by most codes to be embedded in concrete. The solid exterior of these conduits eliminates the possibility of concrete entrance, however, the termination with the connector or coupling can be susceptible to concrete entering the raceway.

The UL 514B testing procedure requires the connector or coupling to be assembled to the conduit inside a special concrete form. Then Portland-type concrete is poured into the form and over test samples. Then the concrete slurry is vibrated to remove any trapped air, and allowed to cure. After concrete curing, the fittings are chipped out of the concrete and examined for concrete penetration.

Although compression style connectors and couplings pass these tests in all trade sizes because of the gland ring design, the set screw types may have difficulty conforming to UL or CSA concrete penetration requirements. When the set screw is tightened onto the conduit, the fitting and/or conduit material will “yield”, or stretch, enough to create an opening at the conduit/ fitting connection.

Set screw fittings in the smaller (1/2″, 3/4″, and 1″) trade sizes are less likely to stretch to the point that would permit entrance of concrete. However, 1-1/4″ and larger size fittings will yield enough so that concrete can enter the raceway. UL and CSA will accept product carton marking that specify “Concrete-Tight When Taped” on fittings that cannot pass testing, since the tape prevents entrance of concrete into the raceway. The taped joint must completely encircle the conduit/ fitting connection. We recommend using duct tape or similar type of durable tape.

Fittings for Wet, Damp, and Rain Tight Applications

Threadless fittings intended for use in wet locations are marked “Wet locations” on the fitting or its smallest unit shipping container. Fittings marked “Raintight” are suitable for use in “Wet Locations”. ”Wet Locations” fittings are sometimes referred to as“Raintight”.

A threadless fitting designed for use in wet locations requires a gasket or sealing ring installed between the fitting and a box shall be installed only with the specific component marked on the fitting’s smallest unit shipping container.

(NOTE: “Wet Locations” or “Liquidtight” fittings are not necessarily suitable for use in applications where submersion in water is expected.”Wet Locations” fittings are not necessarily considered “Liquidtight.“Liquidtight” fittings are intended for use in typical wet locations and also in “wet” industrial environments which may contain machine oils and coolants.)

RMC and IMC fittings for use in industrial applications involving sprayed mineral oils and coolants are marked “Liquidtight” on the fitting or its smallest unit shipping container. Threadless fittings intended for embedment in poured concrete are marked “Concrete-tight” or “Concrete-tight when taped” or ”WetLocations” on the fitting’s smallest unit shipping container.

The term “Raintight” was removed from UL 514B due to NEC changes that removed the term in reference to EMT and rigid fittings, and the term “Wet Locations” is now required.

Fittings listed as “Wet Locations” are also “Concrete-tight” and can be installed anywhere liquids might come in direct contact with the electronics, such as a slow drip or a strong flow. To ensure the proper fittings are used in these environments, look for the package or label to state “Wet Locations” and be listed to UL 514B. Sometimes, the package may say “Raintight” instead of “Wet Locations,” but it should still state that it is listed to the UL.

(NOTE: Taping is adequate to prevent the entrance of concrete aggregate into the raceway or box. Concrete aggregate consists of

cement combined with an inert material such as coarse sand. When hardened, such aggregate may be abrasive and might pose a risk to

abrade conductor insulation or effectively reduce the area inside the raceway. Fittings listed as” Wet Locations” are also “Concrete-tight”. The term “Raintight” has been removed from UL 514B as the result of NEC changes that removed the term in reference to EMT and Rigid fittings. The term “Wet Locations” is now required.)

Threaded Fittings

Threaded joints, both fitting to conduit and fitting to threaded integral box entries, shall be made up wrench tight.

(NOTE: Avoid excessive force. Generally, a force equivalent to hand tight plus one full turn with an appropriate tool is recommended. This should assure engagement of at least three full threads.)

Conduit bodies generally have an integral bushing to provide a smooth surface for conductors when pulled. This bushing is often mistaken for a conduit end stop. It is not necessary that the conduit be inserted flush against this bushing to assure a secure joint

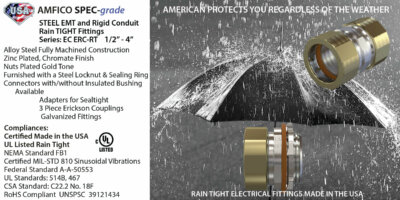

Our fittings are GUARANTEED 100% Rain Tight and have been UL Listed accordingly. All AMFICO Rain Tight fittings are furnihsed with gold toned nuts for easy inspection.

Fittings feature a EZ Torque precision machine compression type assembly and provide a raintight and concrete tight connection to prevent damage from the elements and ensure continued high performance. Rugged steel construction with a zinc plated and chromate finish helps preserve integrity Connectors include steel locknut and sealing ring to provide seal on the box. electrical boxes or enclosures.

Click on image to enlarge image

You can get Free Product Sample Here

Not only will we send you the sample you requested but ask for a Made in USA T-shirt.

The emphasis on support is primarily placed on the conduit. Liquid tight or seal tight Fittings have a criteria as follows:

Conduit is required to be supported adequately, and bending is restricted to 360 degrees total.

Please refer to the following for further details and complete information:

1. UL 360 – Safety standards for liquid tight flexible steel conduit

2. UL 514A and 514B – Safety standards for outlet boxes and fittings

3. W-F-406 – Federal specification: Fittings for cable, power, electrical and conduit, metal, flexible

4. NEMA FB-1 – Standards publication: Fittings, cast metal boxes and conduit bodies for conduit, electrical metallic tubing, and cableFederal

6. Federal standard H-28 (Threads)

2014 Code Language:

348.30(A) Securely Fastened. FMC shall be securely fastened in place by an approved means within 300 mm (12 in.) of each box, cabinet, conduit body, or other conduit termination and shall be supported and secured at intervals not to exceed 1.4 m (4 ½ ft).

Exception No. 4: Lengths not exceeding 1.8 m (6 ft) from the last point where the raceway is securely fastened for connections within an accessible ceiling to a luminaire(s) or other equipment. For the purposes of this exception, listed flexible metal conduit fittings shall be permitted as a means of support.

See the actual NEC text at NFPA.ORG for the complete code section

PIB or plastic insulating bushings must be used in conjunction with 2 locknuts when connecting threaded rigid or IMC conduit, containing No. 4 or larger un-grounded conductors, to boxes or enclosures.

Bushings composed entirely of plastic cannot be used to secure conduit to the enclosure. A locknut→ is required on the inside and outside of the enclosure in addition to the plastic insulating bushing. The temperature rating of the PIB must not be less than the insulation rating of the conductors.

AMFICO’s non-metallic insulated bushing with trade sizes of 1/2″ to 6″ provides female NPT threaded connection for s tight secure fit. It has plastic construction to resist corrosion for longer service life. The bushing has reinforced ribs for added grip and impact-resistant plastic insulation to protect wires from damage. Provide an EZ Pull ever for large diameter wire. Material, as molded, is able to withstand temperature up to 105 ° C PIB Learn More →

Torque ratings for all fittings are specified in UL Bulletin 514B. Our fittings are steel, and precision machine torque values are EZ to obtain with either our EZ Compression Nuts or Steel Set Screws in machined drill and tapped holes.

The fitting we are most asked about are Cord Grip Connectors which act as strain relief and the torque values – Here is a chart.

Use of Anti-Short Bushings for Terminating Type MC Cable

There has been much confusion within the Installation and Inspection communities regarding the use of anti-short bushings for terminating Type MC cable. The confusion stems from the fact that some MC cable manufacturers include anti-short bushings with their cable. The inclusion of anti-short bushings with coils or reels of MC cable is based on historical practice relating to the requirements of 320.40 of the NEC, which mandates the use of anti-short bushing or its equivalent protection for Type AC Cable

Fittings used with Type MC Cable are required to be listed per 330.40 of the NEC. NEMA supports the use of listed fittings for MC Cable. The design of these fittings may or may not include an insulated throat however, they are required to be provided with a smooth, rounded end stop so that the metal sheath of the cable will not pass through and the wires will not be damaged in passing over the end stop. Whether or not an insulated throat is part of the listed product, these listed MC fittings do not require an additional anti-short bushing. Anti-short bushings that may be supplied by MC Cable manufacturers are for optional use by the installer, however, they are not required.

ROP #7-116 from the May 2001 Report on Proposals (ROP) for the 2002 NEC was a proposal seeking to require anti-short bushings on all MC Cable termination installations.

The following is an excerpt from the Panel statement rejecting the proposal:

Anti-short bushings are not required for Type MC cable in accordance with the listing for the product. The termination fittings approved for use with Type MC cables are designed

such that the wires will not come in contact with the cut edge of the armor; the throat of the fitting is small enough to prevent contact with the armor. Type MC termination

fittings perform the same function for Type MC cable as Type AC terminations plus the anti-short bushing do for Type AC cable.

NEMA supports the uniform adoption and enforcement of the NEC and recommends that local Authorities Having Jurisdiction follow the requirements of NEC Section 330.40, Boxes and Fittings for MC Cable. Section 330.40 requires that the fitting be listed, but does not mandate the use of an anti-short bushing.

Outside Diameter Tolerances (mm)

For trade size 1/2″ t0 2” ±0.005 ±0.13

For trade size 2 1/2” ±0.010 ±0.25

For trade size 3” ±0.015 ±0.38

For trade sizes 3 1/2” & 4” ±0.020 ±0.51

What is the difference between NPS and NPT threads?

NPS = National Pipe Straight

NPT = National Pipe Thread

Both NPT and NPS have the same thread angle, shape, and pitch (threads per inch). However, NPT threads are tapered sharply angled and NPS threads are straight (parallel). Both threads have a 60° included angle and have flat peaks and valleys. Sharply angled threads (NPT) are very critical to joint being tight with no leaks. While fitting correctly NPT will seal a joint. Whereas, Straight Pipe Threads will require sealant or tape to typically complete the seal or a gasket or sealing washer (O-Ring) to create a seal. While NPT and NPS threads will engage, they do not seal properly with each other.

HEADS UP:

While NPT and NPS threads will mechanically engage, they do not seal properly with each other.

Our Other Resources to Consider

Distributors:

All American Fittings products are sold in standard carton quantities. Distributors may not split cartons without a split carton surcharge. Used material is never allowed to be returned nor is broken carton quantities. Read our Distributor Return Policy.

Contractors:

I am a contractor and my project is over “HOW DO I GET A RETURN FOR THE UNUSED FITTINGS” – Please refer your question to the Distributor where you purchased our products for their return policies. The Distributor is the sole source for your question but you should know – No materials over 12 months from the date of sale can be returned. No return is permitted without an RGA number provided by the factory and gained through the distributor. We will accept product returns where the material of construction is defective or may not fit the customer application. All returns must have prior approval from our customer care center and you should know restocking charges. may apply.

Distributors should contact Customer Service

Contractors should always consult their point of purchased distributor for that distributor’s return policies.

All American Fittings products are sold through electrical supply houses throughout the United States. Contact your local supplier. While all recognized electrical distributors can furnish you with our products, our ADP Signature Products are full stocking supply houses. Contact us for a list of those ADP Signature Partners.

99% of ALL products sold by AMFICO in both numbers of units and sales dollar revenue are indeed Made in the USA → at our factory in Fair Lawn, NJ. Be confident that you can always get a certificate of compliance for the products you purchase. We NEVER CAMOFLAUGE products like many competitors. We are committed to manufacturing in the USA.

Contact our Customer Service Department for product samples. Most product samples are free of charge and are normally shipped out the next day.

Most orders ship within 24-48 hours after receipt of the distributor’s order. With 5 warehouses throughout the USA an AMFICO product is always close to your location. We pride ourselves in fast turnaround service and in fact same-day shipments when requested.

For ADP Signature Distributors our minimum order is $100.00 for NON-ADP Signature Partners it is $500.00 min. For all accounts, the minimum order value will be waived for UPS RED SHIPMENTS billed to your account.